Some undercarriage mechanics often take a gamble when it comes to getting the right tension on the tension device of an undercarriage. In fact, there is only one guideline to get the right tension and that is the user manual of the machine, which contains the correct tension prescribed by the manufacturer. And even more important; it also contains the various ways in which these must be measured. To give you an idea about this, we have provided an example below from a Takeuchi manual. For some other brands and sized of machines can this be a different matter.

The tension device

The tension that is applied on the track links or rubber tracks is set on the tension device. The tension device can be build in various ways selected by the manufacturer of the machine.

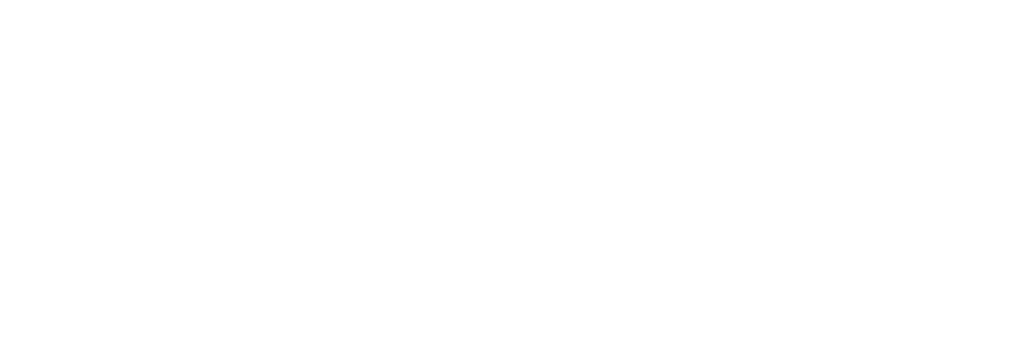

By pumping grease onto the grease gun, you can adjust the position of the idler in relation to the frame. You can do this by pumping grease into the tension device with a grease pump via the grease nipple, which is located on the tension device (usually found near the inspection hatch). The rod that comes out of the housing of the grease nipple will ensure that the idler is positioned to put the rubber tracks or chains on the right tension.

When the track links or rubber tracks are too tensioned, or when you need to remove the chains or tracks from the undercarriage, you can loosen the grease nipple to release tension and bring the idler inwards towards the frame. Loosen the grease nipple carefully and certainly not too far, because there is a lot of pressure on the tension device.

Check whether the tension on the tension device is correct

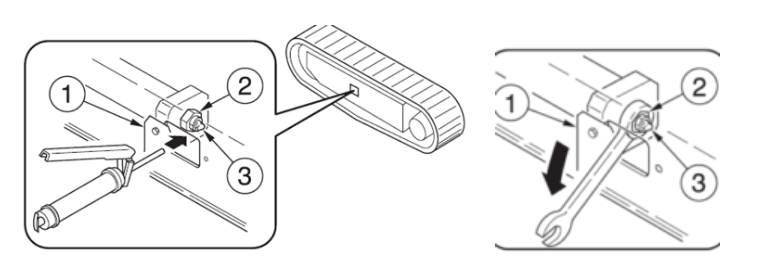

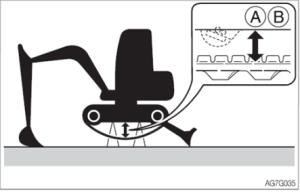

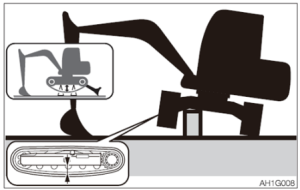

Before using the machine, you should check the tension of the track links or rubber tracks regularly. Machine operators that know their machine well, can feel whether it is tensioned correctly when they step on the track links or tracks when entering the cab. If the tracks or track links sag, the tension of the tension device might not be adjusted correctly. If you want to check the tension of your track links or rubber tracks, it usually starts with freeing the undercarriage, by raising or jacking it.

After raising the undercarriage, let the tracks or track links run in the forward direction for a while. By doing that, the idler will move as far forward as possible, so the tension device will be as tension-free as possible.

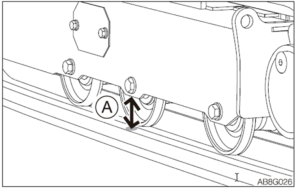

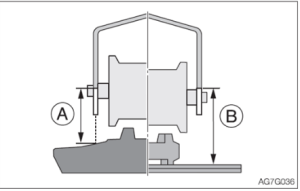

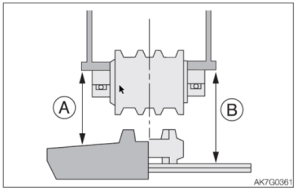

The tracks will sag below the undercarriage and there you need to measure the sag the tracks or track links. You should do this in the correct way, as described by the manufacturer, which is usually the same as in the example below.

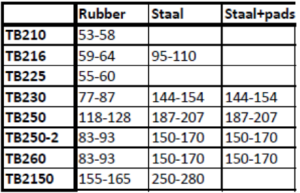

Depending on the type of the undercarriage, these sizes may differ, as a rubber track is lighter than an undercarriage with steel track shoes. When you mount pads on a steel undercarriage, the track links will naturally sag more below the undercarriage than with a rubber undercarriage, especially on heavier machines. Note; the undercarriage has to remain raised during measuring.

The construction of the undercarriage and the various types of rollers will give a measure which is described above as A and B. A is for the rubber tracks, and B for the track links with track shoes.

Depending on the length of the rubber track, the weight of the machine and the construction of the undercarriage, the manufacturer determines how far the track may sag in order to run perfectly below the undercarriage.

The right tension

The right tension for your tracks can only be found in one place: the manufacturer’s user manual of your machine brand. The manufacturer determines the right tension based on his experience, knowledge and manufacturing. A very worn track or undercarriage part influences your travel experience. This does not mean that the track will travel better if you keep to the measurements above. But, these measurements will give the longest possible working life for the complete undercarriage from new.

If you still experience problems after you have checked the tension, it may well be due to other worn parts of the undercarriage. The measurements for these parts can also be found in the maintenance manual.